QS Energy Issues Chairman's Letter

SANTA BARBRA, CA -- (Marketwired) -- 05/23/16 --

Chairman's Letter

The Value Proposition of Our Patented AOT™ Technology in Today's Efficiency-Minded Energy Industry

What technology is QS Energy seeking to commercialize within the global energy industry?

QS Energy is the only vendor in the world selling and leasing industrial hardware based on the principles of "electrorheology", or the use of electrical fields, to optimize the performance of crude oil pipelines. Our flagship product is called AOT, for Applied Oil Technology, and was jointly developed by Temple University's Department of Physics/College of Science and Technology in Philadelphia and is protected by 47 worldwide patents and patents pending. When installed at pumping stations on commercially-operated pipelines, AOT increases flow volume and thereby improves the economics of the operation of virtually any size or configuration of pipeline.

How does QS Energy plan to make money? What are the revenue streams it has available as an entity active in the energy sector?

QS Energy is establishing a strong leadership position within the $6 trillion global energy industry with a tight focus on hardware which uses electrical charges to change the mechanical behavior of crude oil. In simple terms, our AOT system subjects crude oil to a high-voltage/low-amperage electrical field to reduce its viscosity, which permits it to flow in higher volume. By lowering the "thickness" of crude oil and its resistance to flowing freely, our technology improves the performance of pipelines. Our revenue model is two-fold. The Company's proposed primary income is based on AOT Equipment Lease/Option to Purchase Agreements. Due to our ability to configure customized AOT deployments to deliver optimal results to our customers, we are seeking to structure AOT installations pursuant to lease agreements with an initial term of no less than 4 or 6 months, and an option to extend the agreement for 84 months. As documented in an 8-K filing on August 2, 2013, the first such agreement for a four-vessel AOT system, installed to test the commercial efficacy of our technology, generated $240,000 USD revenue for the Company and included an option to purchase the equipment outright at any time for $4.3M USD.

A second similar contract entered into on July 15, 2014, provided an initial term of 4 months and an 84-month extension option based on a monthly lease revenue model of $20,000 per month. This single-vessel AOT installation on a primary condensate line serving the massive Eagle Ford Shale formation provided an option to purchase the system for $1.2M USD during the initial term. QS Energy intends to provide each customer with AOT deployment proposals based on their highly specific technical requirements and other issues before we determine final pricing on an installation, including and up to potential return on investment (ROI) for our customer. Therefore, per unit pricing, lease terms and option to purchase price points may vary significantly depending on pipeline characteristics, type of oil being transported, operating pressure, number of units, etc.

Photo of an AOT Viscosity Reduction System in the field during a beta installation on a pipeline in Udall, Kansas. This primary mid-continent line feeds into Cushing, Oklahoma, often referred to as the “Pipeline Crossroads of the World” and is home to a tank farm with a 90-million-barrel capacity, making it the world’s largest crude oil storage facility.

What is the problem that AOT solves?

Our technology seeks to create measurable bottom line opportunities for our customers. First, AOT mitigates the pipeline bottleneck by improving flow, enabling crude oil producers to get their output to market more quickly. Secondly, AOT delivers enormous value to transporters (pipeline operators) by lowering the operating costs (Opex) associated with running their pipelines. We hope to deliver yet more value by increasing their tariff revenue due to the higher volume of crude oil they can move on a daily basis. As an example, an AOT deployment on a 100,000 barrel per day crude oil pipeline with the operator charging a tariff rate of $3.00 per barrel realizing a 2% flow rate increase, would theoretically yield an additional $6,000 in daily tariff revenue, or approximately a $2.19M net gain per year.

What role does Temple University play in testing crude oil and predicting the efficacy of AOT in the field?

Since Temple University's active involvement as a research and development partner of QS Energy began in 2007, both organizations have jointly offered in-depth crude oil composition analysis and viscosity reduction testing based on the latest AOT performance capabilities. Crude oil samples submitted by energy companies to Temple University's College of Science and Engineering in Philadelphia are done so under a material transfer agreement (MTA) or non-disclosure agreement (NDA). The three- or five-gallon samples are subjected to a controlled electrical field to suspend the naturally occurring impurities in unrefined oil, which re-creates the effect achieved by AOT.

Over the past four years QS Energy has underwritten the testing of dozens of such samples from most of the primary oil production regions of the world. Analysis conducted under the supervision of Dr. Rongjia Tao, the chair of the Department of Physics at Temple University and a leading researcher in the development of technologies based on the use of electro-rheological principles, results in a series of assessments which include a room temperature baseline and an impurity content (asphaltene and paraffin) study. Once a determination is made of the viscosity reduction level possible through the use of the AOT technology, further data is collected in an AOT On Site Questionnaire provided by the prospective customer and reviewed on a strictly confidential, non-disclosure basis. Using proprietary software to accurately predict maximum flow rates, probable pump station energy savings, and possible increased toll rate revenues, QS Energy engineers and technicians perform a hydraulic analysis based on length, diameter and other specific characteristics of the target pipeline. The resulting AOT Preliminary Case Study Analysis, typically delivered within 30 days of the submission of the crude oil sample, provides a detailed proposal showing the pipeline system efficiencies and economic benefits which can be expected from the deployment of a customized AOT installation.

How does laboratory testing at Temple University compare with what AOT can deliver on pipelines?

Starting from the fabrication and deployment of the first commercial AOT unit, it has always been our goal to optimize the target pipeline as closely in line with results achieved on crude oil sample analysis in the laboratory at Temple University. We're pleased that the optimized "next generation" AOT system appears to improve our ability to predict the viscosity reduction level possible in a commercial deployment based on the tests conducted using a controlled electrical field under optimal laboratory conditions. However, results from forecasts contained in the hydraulic analysis reports we provide to prospective customers can differ due to scalability and other variances. In such cases, the economic and operational gains derived from an AOT installation can still be reasonably expected to result in Opex and tariff revenue benefits sufficient to achieve a meaningful return on investment. We recently documented the improved performance capabilities of the value engineered AOT technology in a February 8, 2016 news release. As disclosed in an SEC filing on March 31st, 2016, this is a re-deployment of AOT on a high volume condensate pipeline which afforded us an opportunity to prove our efficacy on ultra-light oil, the fastest growing segment of production from the nation's shale formations. AOT's improved ability to reduce viscosity, maximize flow volume, and reduce operating pressure in the treatment of condensate may also expand our reach to a broader range of feedstock and accelerate our time to market.

Why are crude oil pipelines so important to the industry and the economy?

Pipelines are universally acknowledged to be the most efficient, environmentally friendly and cost-effective way to move crude oil. As you would expect, there is a massive pipeline infrastructure crisscrossing North America, Europe, Africa, the Middle East and virtually everywhere crude oil is produced. Alternative transportation methods such as rail and freight truck are significantly costlier and obviously cannot match the sheer capacity of the daily flow carried by pipeline. The industry's largest, or primary pipelines, are engineered to transport hundreds of thousands of barrels of oil daily from the oil field to downstream refineries.

Why is QS Energy focused on improving crude oil pipeline performance?

The bulk of the world's pipelines were constructed in the 1960s and 1970s, with additional lines becoming ever more expensive and difficult to construct due to obstacles in gaining approval and permitting. With the advent of highly advanced drilling techniques, or Enhance Oil Recovery (EOR) methods, starting in the mid-1990s and continuing until the present day, the amount of upstream production being extracted from shale formations in the U.S. and internationally has skyrocketed. The result is that existing pipeline capacity is woefully inadequate, causing costly delays, loss of revenue, and forcing the use of road and rail as far less safe and practical transportation methods. It is this massive global challenge of insufficient pipeline capacity that has provided QS Energy with the opportunity to greatly improve the performance of pipelines which are the lifeblood of the industry.

Over 200,000 miles of pipeline transport liquid hydrocarbons across North America, delivering in excess of 13,000,000 barrels of crude oil annually from well hole to refineries. Map courtesy of Canadian Association of Petroleum Producers.

Does AOT technology have competitors?

None of which we are aware. QS Energy's AOT Viscosity Reduction System is the energy industry's only solid-state equipment using electrical fields to reduce the viscosity of crude oil, enabling a wide spectrum of grades to flow more efficiently and economically through pipelines. Our intellectual property portfolio includes 47 domestic and international patents and patents pending, which have been developed either independently or in conjunction with and exclusively licensed from Temple University. The challenge of keeping the world's ample supply of crude oil moving efficiently from well hole to market via pipeline is daunting. Producers and transporters spend enormous sums on chemical additives (diluents and drag reduction agents) and the use of heat (trace heating, bulk heating). While the use of additives and heat can reliably achieve the desired viscosity reduction (resulting in a higher Reynolds number(1)), lower friction factor and reduced pump station power requirements, additives are costly, displace a large percentage of the volume of feedstock being transported, and must be removed during the final refinement process.

Typically, additives dilute the oil by as much as 25 to 30 percent, effectively reducing pipeline capacity by the same ratio. With diluents accounting for upwards of $13 per barrel of additional cost for bitumen (heavy-weight crude oil), reducing the amount of additives used to transport heavy crude oil provides an easily defined net savings. We believe AOT has gained the interest of producers and transporters globally due to its unique positioning within the industry as a solution that uses electrical charges to improve flow whether the feedstock contains diluents or not. SCADA (supervisory control and data acquisition) data gathered during closed loop and commercial pipeline usage suggests that by reducing the amount of diluent used in pipelines, AOT can reasonably be expected to deliver the dual benefit of lowering operating expense while increasing tariff revenue. Prior to installing AOT systems on two domestic commercial pipelines, QS Energy performed extensive ROI analysis on behalf of our clients based on their existing operational overhead, volume of flow, and revenue growth potential based on their published tariff rates to predict the extent of these benefits.

Has the effectiveness of AOT been independently tested and proven?

Independent third-party testing by organizations which include the U.S. Department of Energy, PetroChina/The China Petroleum Pipeline Bureau (CPP), fluidics consulting firm ATS RheoSystems, and our R&D partner Temple University, have consistently and repeatedly proven the efficacy of AOT to: 1) improve flow, 2) increase the volume of transported oil, 3) mitigate bottlenecks, 4) reduce the amount of energy used to operate the line and, 5) decrease pipeline pressure drop. Appendix I: 'Published Papers and Studies' on page 14 provides testing analysis reports for your review.

What is the science behind AOT?

Through a process known as dielectrophoresis, the electrical charge AOT generates causes a conformational change to the molecular structure of the naturally occurring paraffin and asphaltene content in the crude oil. These randomly distributed particles bundle together into tight packets aligned in chains. By aggregating the suspended particles into short chains traveling in the direction of flow, AOT decreases viscosity and increases pipeline flow rate, optimizing performance for operators and transporters while lowering their capital requirements. In addition to decreasing viscosity along the direction of flow, this unique chain formation also increases viscosity perpendicular to the direction of flow. Currently the Company is studying this effect to determine AOT's ability to potentially suppress the onset of turbulence. Suppressed turbulence reduces turbulent friction and substantially increases flow rate, far beyond the benchmark set by reduced viscosity alone. These factors combine to minimize costs and increase throughput, while mitigating energy loss.

The impact of viscosity reduction for pipeline transportation systems is well known and, in fact, a large portion of the products serving the midstream sector seek to achieve this goal. Fluid viscosity plays an important role in the function of any hydraulics system. It is one of the main sources of internal fluid friction which is responsible for major pressure loss, a factor that must be overcome by a strong pressure gradient created by a pump. Diluents, DRAs, flow assurance additives, and the application of heat via trace heating and bulk heating systems are used aggressively to reduce viscosity and encourage a laminar (smooth, predictable) flow. AOT can play an important role in supplementing these methodologies, enhancing their benefits and further maximizing pipeline performance. By contributing to the reduction of friction, AOT has shown an ability to counter pipeline pressure drop which slows flow, thereby improving the efficiency of the system as a whole. The reduction of power required for flow also reduces demand on pump station motors, directly reducing the amount of carbon dioxide (CO2) emitted.

How does AOT seek to meet the operational goals of pipeline companies?

Many companies choose to operate their pipelines at a constant pressure or power level. In that case, viscosity reduction will effectively increase pipeline capacity. Decreases in viscosity will, if strategically deployed, increase throughput and revenues significantly, both of which have been proven during test deployments of AOT. Lower viscosity also relieves bottlenecks, and provides companies with the ability to unload crude storage more quickly. This allows for a more flexible schedule, and shorter load times. Reduced wax deposition and suppressed pour point, two effects currently being studied and confirmed in laboratory testing, may also provide substantial ancillary benefits to certain customers.

During the eight years of research and development of AOT, what stages of design modifications have occurred to bring it to full commercialization?

Following the development of a series of prototypes of the AOT technology during the R&D phase at Temple University, we conducted a succession of field tests of full-scale units, both on closed loop pipelines and later on fully operational, high volume commercial pipelines. Earlier this year, in collaboration with one of the largest pipeline operators in North America, we completely value engineered AOT to improve the overall efficiency of electric field generation, which in turn has resulted in the most efficient performance of AOT to date. Although we undertook this re-design of AOT to better enable it to treat condensate, an ultra-light grade of crude oil, we believe this new level of viscosity reduction will improve its performance across a broad range of grades of crude oil and we believe also make the economics of deploying our technology even more compelling.

Following the recent value engineering of an AOT Viscosity Reduction System, a vertically-oriented single-vessel unit was installed on a primary line providing takeaway for the Eagle Ford Shale, the most active shale formation in the world.

Does AOT produce results on a wide spectrum of crude oil pipelines?

Absolutely. By design, we believe AOT is capable of maximizing the performance of virtually any pipeline infrastructure, regardless of length, diameter, flow rating, volume, or grade of crude oil carried. Each AOT system consists of a 36-inch diameter ASME-approved pressure vessel, connector pipes, inlet and outlet nozzles, and a skid platform for positioning on a gravel and concrete substrate. Once installed at the chosen pumping station, AOT's modular design allows for deployment in one or multi-vessel configurations. Multi-vessel installations are connected in parallel to adapt to the necessary pipeline capacity. As a result of our research and development program with Temple University and 8 years of collaboration with corporate executives and petroleum engineering teams at over 20 top-tier energy companies, we believe AOT is uniquely positioned as a cost-efficient, low maintenance solution with documented efficacy. Lower flow, smaller diameter pipelines can expect similar flow volume and performance improvements as higher volume, larger diameter lines. The first commercial use of AOT used four pressure vessels in parallel for a cumulative capacity of 500,000 barrels per day.

Can QS Energy provide a compelling case for the use of AOT throughout the industry?

Yes. In addition to providing our AOT systems to the Midstream, the largest sector in the energy supply chain, we are in discussions with transporters in the gathering and upstream sector, operators of downstream refinery, rail and marine offloading facilities, as well as tank battery recirculation systems where lower viscosity would be desirable. The Company also has an innovative crude oil heating technology in the development phase, targeting the needs of E&P entities active in the Upstream. Designed specifically for feeder lines, gathering lines and other field-to-transmission line infrastructure, JHT (Joule Heat Technology) is a highly energy-efficient heating system that applies an electric current directly to crude oil within an ASME-certified pressure vessel. Due to factors such as high viscosity, density, poor mobility and cold ambient temperatures, the energy industry invests heavily in trace heating and other electrical and natural gas powered systems to ensure the safe, reliable and cost effective transport of crude oil. Our patent-pending JHT system is electrically powered, compact and adaptable to a variety of applications, from extreme cold weather to corrosive saltwater environments, on pipelines, in oilfields and marine, rail and truck offloading facilities.

Why is the Midstream the most valuable market for AOT?

Midstream operators represent a strong and ready market for AOT here in North America and overseas. Collectively they transport the bulk of the world's crude oil output via the 400,000 miles of ever-expanding global crude oil pipeline infrastructure. Domestically, midstream companies deliver a large percentage of the U.S. daily production of 9.2 million barrels per day through 160,000 miles of crude pipelines. The pipeline operators' business model is to charge a tariff to transport each barrel of oil through their pipeline. Due to the high daily volume of oil being transported and its value as a commodity, even incremental performance efficiencies of 10 to 15 percent viscosity reduction are of high appeal from both an overhead reduction and tariff revenue standpoint. Among the use case factors taken into consideration in determining the benefits of AOT deployments are expected flow rate increases within the context of the operator's tariff rates. In conjunction with Temple University's in-depth crude oil composition analysis/viscosity reduction testing, and our hydraulic analysis measurements, a projected ROI for our industrial hardware is generated and provided to the customer. With a growing history of SCADA (supervisory control and data acquisition) gathered from pipeline tests and commercial installations, the Company is continuing to study the combined benefits of increasing flow volume and reducing of the use of diluents to more accurately calculate the ROI of proposed deployments. For further data specific to the domestic pipeline system, the Association of Oil Pipe Lines offers a summary on page 5 of their U.S. Liquids Pipeline Usage & Mileage Report (November 2015).

Which are the largest Midstream companies?

The North American and overseas Midstream sector form the backbone of the global energy industry. Industry data shows abundant evidence that upstream producers are often caught with oversupply in relation to the takeaway capacity available to them. Although primarily engaged in the operation of crude oil and natural gas pipelines, many are becoming vertically integrated and are involved in the processing, storage and marketing of oil, gas, condensates and natural gas liquids. A list of the Top 15 Midstream/Infrastructure companies compiled by Bloomberg and HIS Global on December 31, 2013 is available in the IHS Energy 50 report (page 6).

What is QS Energy's AOT inventory and where has AOT been deployed commercially?

The Company currently owns five AOT pressure vessels; one of which was recently deployed in South Texas under an AOT Equipment Lease/Option to Purchase Agreement with provisions to extend the lease or purchase the equipment. The remaining four AOT pressure vessels will be re-deployed either separately or together depending on the target pipeline infrastructure. In the period following fabrication of the first AOT prototype in May 2013, two lease agreements have resulted, each to test the commercial viability of AOT. One was an installation on a 500,000 barrel per day mid-continent pipeline operated by a $36 billion company, and the second, a deployment on a 100,000 barrel per day pipeline serving the Eagle Ford Formation and operated by a $39 billion entity.

The first field deployment was a beta installation to test the efficacy of AOT on a high volume commercial pipeline. The current South Texas test deployment is a vertically positioned AOT system specifically optimized for condensate, the fastest growth category of shale formation output today. With the lifting of 40 years of federal export restrictions governing unprocessed crude oil, the energy industry anticipates strong demand for U.S. condensate from foreign buyers. Demonstrating our technology's effectiveness to more efficiently and economically transport condensate in pipelines, at condensate splitter plants, and within offloading facilities represents an enormous opportunity for AOT and is one we intend to pursue vigorously.

Are additional installations of AOT in process?

QS Energy is currently in non-disclosure level discussions with pipeline operators in six of the world's primary oil transportation corridors. The Company has also furnished detailed engineering proposals to two transporters in the U.S. and leading energy entities in the Middle East, Europe, Africa and Canada, which have resulted in highly specific use case deployment discussions. Custom configurations of AOT systems are only formally proposed following laboratory testing of crude oil samples and sharing of sensitive operational metrics provided under non-disclosure agreements. Among the opportunities in the engineering design phase as prospective collaborative endeavors is the use of AOT technology for subsea deployment at marine offloading facilities in the United States and Norway. The operators of two critical crude oil distribution and storage hubs are seeking performance improvements of their network of feeder lines supplying flow into storage tanks and high volume takeaway pipelines.

What is included in a typical proposal to a pipeline operator and how does QS Energy quantify the expected economic benefits to a potential AOT customer?

After a preliminary analysis of a crude oil sample provided by prospective customers, QS Energy and Temple University conservatively estimate the volume increases we can achieve in the capacity of the targeted pipeline. We also forecast the increased daily tariff revenue of the pipeline and the percentage by which we can improve efficiency following the installation. Furthermore, we then calculate the monthly reduction in Opex and the net financial gain possible for our customer based on this data.

Where is your patent-protected AOT hardware fabricated and are your supply chain partners under non-disclosure agreements?

Industrial Screen & Maintenance, Inc. and Power Service, Inc., both located in Casper, Wyoming, currently serve as our fabrication arm, with various suppliers providing smaller assemblies such as power supplies and electrical (NEMA) enclosures. All are covered with non-disclosure agreements which remain in force indefinitely. In the event of larger purchase orders, additional supply chain partners have been identified. For international orders, initial builds will be American made, however we may need to eventually establish supply chains in various qualified areas.

As CEO of QS Energy, how do you manage the quality assurance and performance standards necessary to commercialize AOT within one of the most demanding industries in the world?

QS Energy takes its responsibility to ensure the highest degree of safety, quality and reliability seriously. As a recognized supplier of technology to pipeline operators, we are an ISO/TS 29001 compliant entity and strictly adhere to U.S. and international engineering standards and practices, including ASME (American Society of Mechanical Engineers), ISO (International Organization for Standardization, AISC (American Institute of Steel Construction), and our equipment has been certified for use in Canada under a CRN (Canadian Registration Number) for pressure vessel quality assurance. Each AOT vessel and all piping, connectors and electrical components are fabricated according to exacting specifications and undergo rigorous pressure testing and other performance protocols prior to transport to the client location. Installation of AOT systems is performed by top-tier civil and petroleum engineering contractors under the direct supervision of QS Energy and our customers' internal technicians.

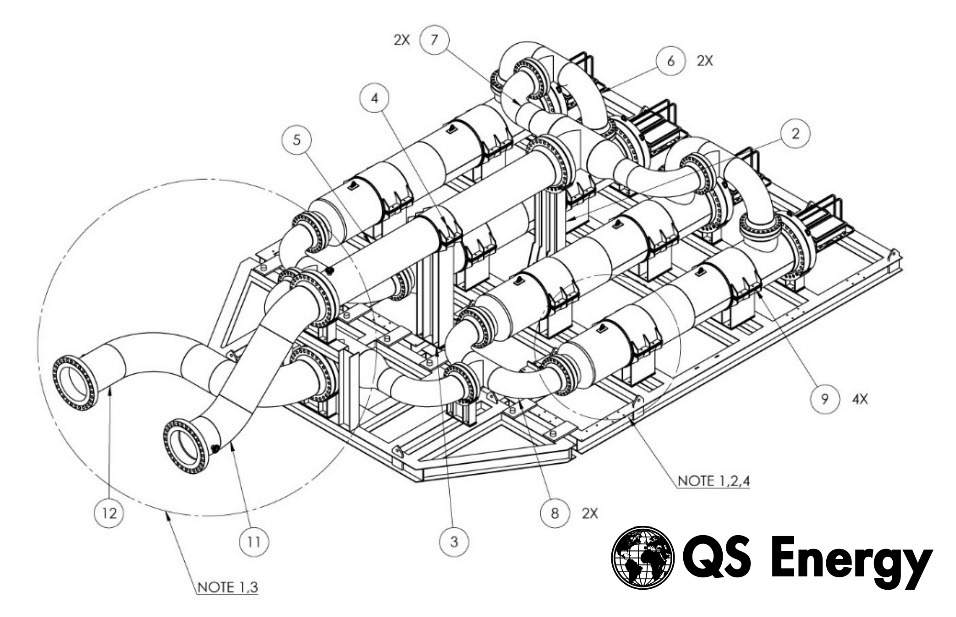

Industrial design schematic of a four-vessel AOT Viscosity Reduction System. Following fabrication and pressure testing, this 110-ton unit was ASME-certified, approved for use in hazardous location Class 1, Div. I. rated areas and installed on a 500,000 barrel per day mid-continent pipeline operated by a $36 billion North American energy company.

What is the process involved in transporting 30,000 pounds of hardware to customers active in remote locations or overseas?

Primary fabrication and pre-installation preparation of AOT systems are performed by our supply chain partners in Casper, Wyoming. This central, Mountain Time Zone location provides delivery capability within two-to-three days by freight truck to leading oil production regions such as North Dakota, Montana, Utah, Colorado, Alberta, Oklahoma and Texas. The inaugural beta deployment of a four-vessel AOT system was trucked on six flatbeds to Udall, Kansas for installation on a 500,000 barrels per day pipeline, representing a payload of 110 tons. QS Energy's distribution of AOT hardware extends to Europe, Asia, Africa, the Middle East and South America through the ports of Houston, South Louisiana and Long Beach, via container and cargo vessels.

Many thanks for your interest in QS Energy.

As Chairman of QS Energy I receive hundreds of requests from investors and brokers each month. Due to SEC regulations and selective disclosure rules, I am very restricted on what information I can provide to individual shareholders and the investment community. However, it has always been my objective to be as forthright and transparent as possible. I invite you to contact us anytime with your questions, comments or suggestions at investor@QSEnergy.com or sales@QSEnergy.com and to review our SEC filings, news releases and other documentation on our website www.QSEnergy.com.

For further information about QS Energy please read our SEC filings at www.sec.gov, and, in particular, the risk factor sections of those filings.

Safe Harbor Statement:

Some of the statements in this release may constitute forward-looking statements under federal securities laws. Please visit the following link for our complete cautionary forward-looking statement: http://www.QSEnergy.com/site-info/disclaimer.

Sincerely,

Greggory M. Bigger

CEO & Chairman

QS Energy, Inc.

www.QSEnergy.com

Investor Relations & Media Contact:

QS Energy, Inc.

Tel: (805) 845-3581

E-mail: investor@qsenergy.com

Source: QS Energy, Inc.

APPENDIX I:

Published Papers and Studies

AOT Video Overview

http://www.qsenergy.com/technology/technology-reports?file=54

Technical papers published by Dr. Rongjia Tao, co-developer of AOT and Chairman of Temple University's Physics Department:

'Reducing viscosity of paraffin base crude oil with electric field for oil production and transportation', Published in FUEL, The Science and Technology of Fuel and Energy. Elsevier B.V. (October 25, 2013)

https://qsenergy.app.box.com/v/Jfuel-crude-oil

'Neutron scattering studies of crude oil viscosity reduction with electric field', Published in FUEL, The Science and Technology of Fuel and Energy. Elsevier B.V. (June, 2014)

http://qsenergy.box.com/v/Neutron-Fuel

'Suppressing Turbulence and Enhancing the Liquid Suspension Flow in Pipeline with Electromagnetic Fields', presented at the Tenth International Conference on Flow Dynamics,

November 25-27, 2013, Sendai, Miyagi, Japan.

https://qsenergy.app.box.com/v/turbulence-2013-tohoku

AOT CASE STUDY

U.S. Department of Energy Field Test:

Save the World Air, Inc. Viscosity Reduction Technology, Casper, Wyoming

Abstract: The Rocky Mountain Oilfield Testing Center (RMOTC) conducted a field test on a prototype of the QS Energy in-line viscosity reduction device at the Naval Petroleum Reserve No. 3 (NPR-3) located 35 miles north of Casper in Natrona County, Wyoming. The in-line viscosity reduction device is designed to reduce the line-loss and increase the flow rate of crude oil traveling through a commercial pipeline, thereby reducing the energy required for crude oil transportation. Reductions in line-loss and gains in pump operation efficiency (i.e., reduced power consumption) were observed on the 4.4 mile 6" schedule 80 metal buried pipeline test loop.

Test Results:

Viscosity Reduction The original viscosity was 81.6 cp. After the AOT device was turned on, it was reduced by 56.12 percent down to 48.95cp. After the AOT device was turned off, the crude oil in the section was gradually replaced by untreated crude oil and the viscosity returned to the original value.

Pressure Loss When the AOT device is turned on, the pressure loss is reduced by 56.12 percent, from 24.8 psi/mile (pounds per square inch per mile) down to 14.87 psi/mile. After the device turned off, the crude oil in the section was replaced by untreated crude oil and the pressure loss returns to the original value.

Conclusion:

Test results indicate that the viscosity reduction device operated successfully and that the AOT 1.2V prototype delivers improved performance over the original AOT prototype tested in October 2011. Pipeline line-loss and pump motor power consumption were reduced for a given flow rate during the observed test. The device may hold potential for energy savings and increased pipeline flow rates for the oil production and transportation industry.

Disclaimer

All statements and expressions are the sole opinion of the company and are subject to change without notice. The Company is not liable for any investment decisions by its readers or subscribers. It is strongly recommended that any purchase or sale decision be discussed with a financial advisor, or a broker-dealer, or a member of any financial regulatory bodies. The information contained herein has been provided as an information service only. The accuracy or completeness of the information is not warranted and is only as reliable as the sources from which it was obtained. Investors are cautioned that they may lose all or a portion of their investment in this or any other company.

Information contained herein contains "forward looking statements" within the meaning of Section 27A of the Securities Act of 1933, as amended and Section 21E of the Securities and Exchange Act of 1934, as amended. Any statements that express or involve discussions with respect to predictions, expectations, beliefs, plans, projections, objectives, goals, assumptions or future events or performance are not statements of historical facts and may be "forward looking statements". Forward looking statements are based on expectations, estimates and projections at the time the statements are made that involve a number of risks and uncertainties which could cause actual results or events to differ materially from those presently anticipated. Forward looking statements may be identified through the use of words such as "expects", "will", "anticipates", "estimates", "believes", or by statements indicating certain actions "may", "could", "should" or "might" occur.

(1) In fluid mechanics the Reynolds number (Re) is used to define the ratio of resistant (inertial) forces to viscous forces to help predict flow patterns and drag.

Released May 23, 2016