ROCKY MOUNTAIN OILFIELD TESTING CENTER

Published on October 25, 2011

Exhibit 10.1

STWA, Inc.:

Viscosity Reduction Test

An assessment of an in-line viscosity reduction device

Naval Petroleum Reserve No. 3, Teapot Dome Field, Wyoming

Final Report for October 19, 2011

Funds-In 2011-A148 (DOE-RMOTC-51141)

STWA, Inc.: Viscosity Reduction Test

Jeanette Buelt, RMOTC

DISCLAIMER: This report was prepared as en account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, nor any of their contractors, subcontractors or their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or any third party's use or the results of such use of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or Imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof or its contractors or subcontractors. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

ABSTRACT

The Rocky Mountain Oilfield Testing Center (RMOTC) conducted a field test on the STWA in-line viscosity reduction device at the Naval Petroleum Reserve No. 3 (NPR-3) located 35 miles north of Casper in Natrona County, Wyoming. The in-line viscosity reduction device is designed to reduce the line-loss of crude oil traveling through a commercial pipeline and thereby reduce the energy required to transport crude oil through pipelines. Gains in pump operation efficiency were observed on the 4.4 mile, 6 inch, schedule 80 buried pipeline test loop.

|

Table of Contents

|

|

|

INTRODUCTION:

|

1

|

|

TEST RESULTS:

|

2

|

|

OBSERVATIONS:

|

2

|

|

CONCLUSION:

|

5

|

|

APPENDIX A

|

7

|

|

List of Figures

|

|

|

Figure 1. State Map of NPR-3

|

1

|

|

Figure 2. Viscosity Reduction Unit and Test Site Tank Battery

|

2

|

|

Figure 3. RMOTC, STWA and Temple University Personnel Gathering Data

|

3

|

|

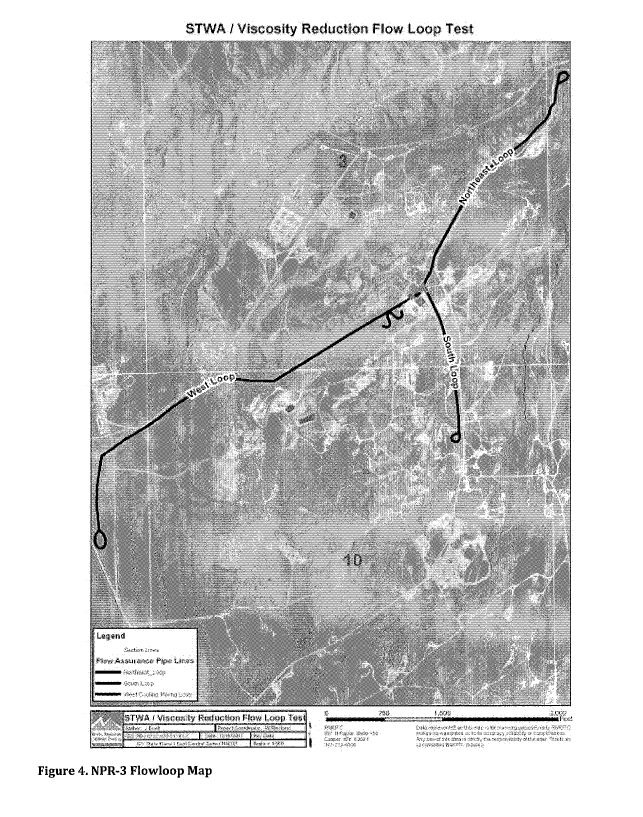

Figure 4, NPR-3 Flowloop Map

|

4

|

|

Figure 5. RMOTC and Temple University Personnel briefing

|

5

|

|

Figure 6. STWA's Viscosity Reduction Unit, Post-Testing

|

6

|

|

Figure 7. RMOTC, STWA, and Temple University Personnel

|

6

|

INTRODUCTION:

The Rocky Mountain Oilfield Testing Center (RMOTC) conducted a field test on the STWA in-line viscosity reduction device (Applied Oil Technology, AOT) at the Naval Petroleum Reserve No. 3 (NPR-3) located 35 miles north of Casper in Natrona County, Wyoming.

Figure 1. State Map of NPR-3

STWA, Inc. (STVVA) of Santa Barbara, California, together with Temple University of Philadelphia's physics department, designed and created the AOT device to reduce the energy required to transport crude oil through commercial pipelines.

The device exposes passing crude oil to a precisely controlled electric field to reduce the oil viscosity. This is intended to reduce line-loss (fluid drag) and pressure, without changing the oil temperature or composition. In a commercial pipeline operation, the intended results would translate into reduced pump power required to maintain constant flow rates, and would thereby deliver energy savings for crude oil transportation.

1

TEST RESULTS:

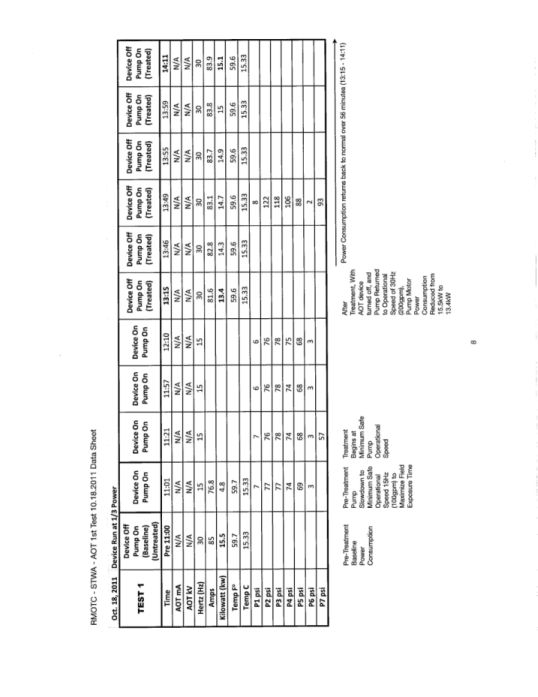

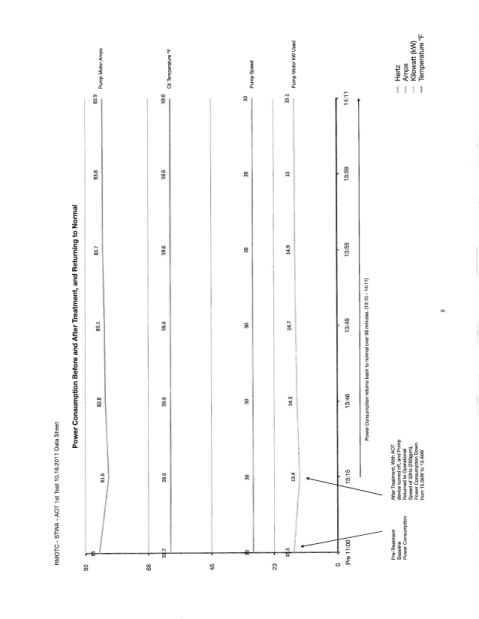

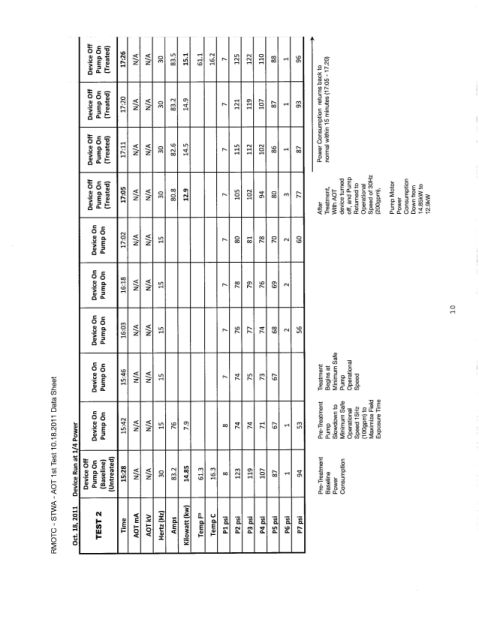

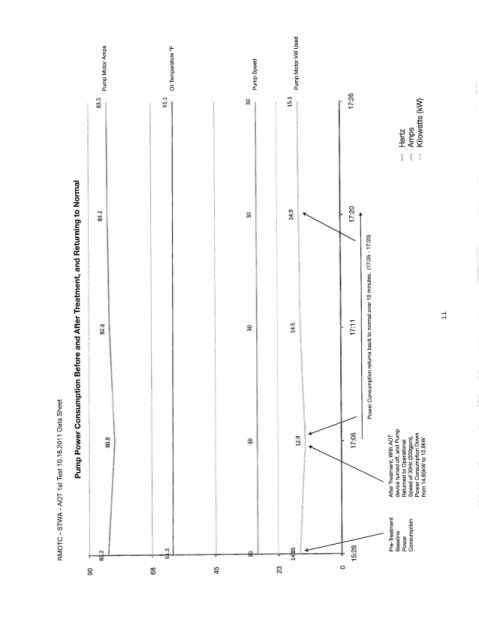

Test results are detailed within Appendix A.

OBSERVATIONS:

In 2011, the AOT device was installed on a flow loop located at the RMOTC field test site in NPR-3. The flow loop - a 4.4 mile, 6 inch, schedule 80 buried pipeline -- was modified specifically to support this viscosity reduction test. RMOTC validated overall system integrity after AOT installation, and filled the loop with field-produced API 34' oil to facilitate testing.

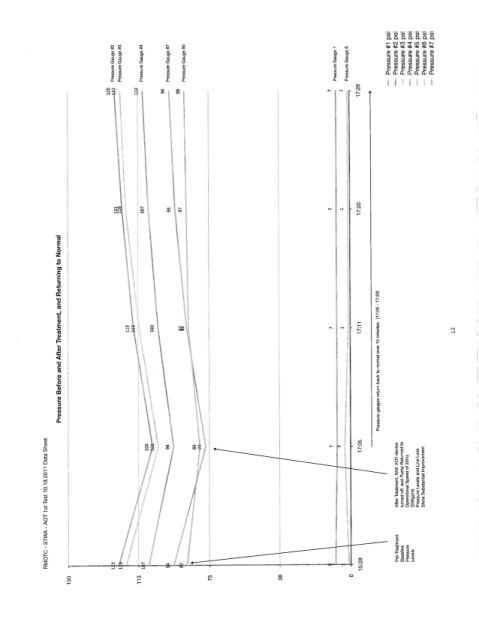

The oil was circulated through the loop to establish baseline hertz, amperage, kilowatt, temperature, and pressure rates. After establishing baseline performance, the AOT device was turned on to measure Its impact on these variables. Both pump motor power consumption and pressure inside the flow loop were measurably reduced with the device in operation, Temperature was not measurably affected by the device operation.

Power consumption was observed to decrease by 13.55% when the device was operating at one third its power capacity. After running for 70 minutes, the device was deactivated, and pump motor power consumption returned to baseline pre-treatment numbers within 56 minutes.

2

Power consumption was observed to decrease by 13.14% when the device was operating at one fourth its power capacity. After running for 75 minutes, the device was deactivated, and pump motor power consumption returned to baseline pre-treatment numbers within 15 minutes.

3

4

CONCLUSION:

Preliminary test results indicate that the viscosity reduction device operated successfully. Pipeline line-loss and pump motor power consumption were reduced for a given flow rate during the observed test. The device may hold potential for energy savings and increased pipeline flow rates for the oil production and transportation industry.

5

This research was co-funded by STWA, Inc. and the Pipeline Research Council International (PRCI). Work was directed by Clarke Turner, Brian Haight, Wes Lintz, Wes Riesland, George Hughes and Jeanette Buell.

6

APPENDIX A

Raw Data

7

8

9

10

11

12